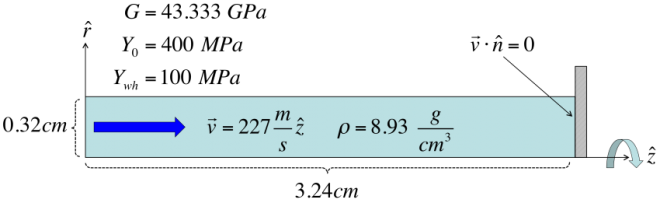

We consider the Taylor high-velocity impact problem which makes use of our high-order, curvilinear elastic-plastic flow model. The problem consists of a cylindrical copper rod impacting a rigid wall. Initial conditions and material properties are specified according to the following diagram:

2D Axisymmetric and 3D Lagrangian Simulations with Q4-Q3 Finite Elements

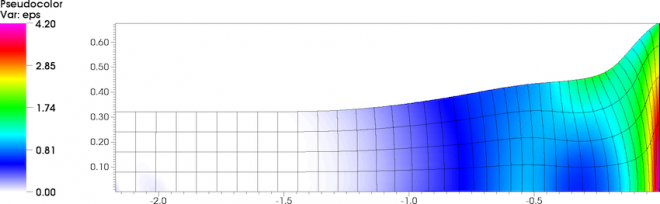

Results for equivalent plastic strain and curvilinear mesh in the 2D axisymmetric Taylor impact problem. Using Q4-Q3 finite elements in 2D gives 25 kinematic and 16 thermodynamic degrees of freedom per zone. High-order curvilinear methods can provide accurate results on very coarse 2D meshes.

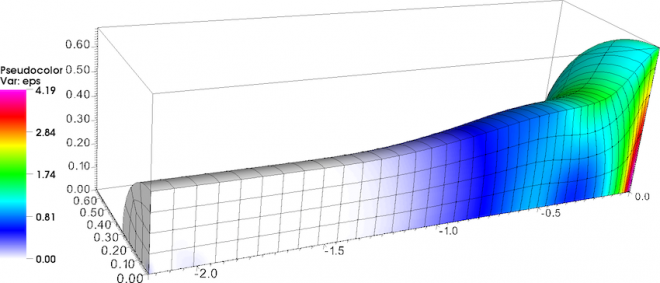

Results for equivalent plastic strain and curvilinear mesh in the 3D Taylor impact problem. Using Q4-Q3 finite elements in 3D gives 125 kinematic and 64 thermodynamic degrees of freedom per zone.High-order curvilinear methods can provide accurate results on very coarse 3D unstructured meshes.

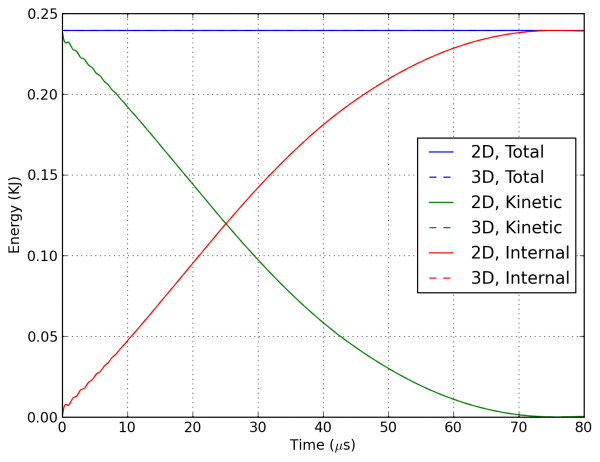

Time dependent results for total, internal and kinetic energies for the 2D and 3D cases. The 2D and 3D methods give virtually identical results and total energy is conserved to machine precision for each case.

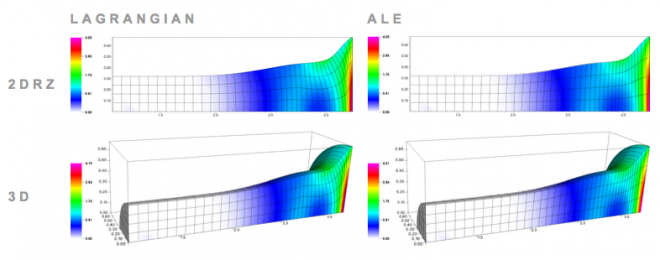

Comparing Lagrangian and ALE Simulations with Q4-Q3 Finite Elements

Comparing results for equivalent plastic strain and curvilinear mesh in the 2D axisymmetric and 3D Taylor impact problem for Lagrangian and ALE simulations. Using Q4-Q3 finite elements in 2D gives 25 kinematic and 16 thermodynamic degrees of freedom per zone. The high-order ALE algorithm provides a 12X speedup in 2D and a 7X speedup in 3D by substantially reducing the total number of time steps (cycles) required.

| Method | Length | Max. Rad. | Max. EPS | Cycles | Run Time |

|---|---|---|---|---|---|

| 2Drz ALE | 2.1738 | 0.6744 | 4.20 | 23,890 | 2.15 min |

| 2Drz Lag. | 2.1738 | 0.6742 | 4.20 | 496,347 | 26.32 min |

| 3D ALE | 2.1739 | 0.6743 | 4.21 | 29,348 | 120.30 min |

| 3D Lag. | 2.1739 | 0.6741 | 4.19 | 509,468 | 869.27 min |