Our confidence in predictions of material behavior at extreme conditions is limited by our lack of knowledge of microstructure and its rate of formation following first-order solidification and solid-solid phase transformations. We are developing a new capability to reliably predict this microstructure by extending our highly successful molecular dynamics (MD) simulations of nucleated microstructures to hydrodynamic length- and time-scales.

This new phase-field modeling capability will employ a real-space representation of the time-dependent Ginzburg-Landau equations in a scalable simulation code amenable to high performance ultra-scale computing, and establish LLNL's leadership to directly simulate, for the first time, experiments of first-order phase transformations under highly dynamic conditions such as observed at the dynamic transmission electron microscope and JASPER.

Technical Description

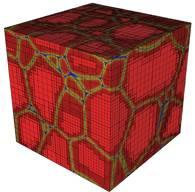

The microscopic structure of a material completely rebuilds itself during a first-order phase transformation. This microstructure includes information about the state of the material (solid or liquid) and the local crystalline structure in the solid. This process is shown in Figure 1 in which large-scale MD are used to simulate solidification during rapid compression.

The nucleated grain-size distribution from the MD simulation is shown in Figure 2 along with the log-normal distribution of a well annealed polycrystal. The distribution at the intermediate length- and time-scales is unknown. Our goal is to develop the capability to reliably predict this microstructure at hydrodynamic lengths and times of interest.

Building upon our calculation of local phase information within the MD simulations, we are developing a continuum model that evolves the same phase-field order parameter. We base our model development on the 3D orientational model due to Pusztai et.al, where a quaternion order-parameter is introduced to represent the grain orientations. Microstructure evolution is driven by the minimization of the total free energy, which results in the evolution equation for the phase order-parameter. We will apply crystallographic-aware phase-field modeling (PFM) techniques to simulate the late-time growth of the nucleated grains shown in Figure 1.

Various numerical approaches are being explored for solving phase-field models. Due to singular diffusivities in the quaternion equations, an implicit time integration method must be employed to avoid small time steps imposed by stability limits. Our initial approach for numerically integrating this model will be to advance the system in an operator split fashion. "The phase order equation will be integrated explicitly using a Runge-Kutta method, which includes the selection of the time step based on the CFL condition." The quaternion system will then be advanced over the same time step as a differential algebraic system, where the algebraic constraint is the unit length of the quaternions, using a backward Euler update.

To solve the coupled nonlinear quaternion system, we will employ a Newton iteration, where the associated Jacobian system will be solved using a fast adaptive composite (FAC) iteration. The FAC iteration requires the solution of a linear system on each AMR refinement level, for which we will employ the SysPFMG solver from the hypre library. Using this code as a testbed, we will be able to experiment with various algorithmic refinements, including the possibility of integrating the fully coupled system (i.e., non-operator-split) as a differential algebraic system with a high-order, single-stage (e.g., implicit Runge-Kutta) integrator.

Mission Relevance and Exit Plan

Upon completion, this new capability will be available to provide a realistic prediction of microstructure for relevant metals and alloys under extreme conditions. Furthermore, our phase-field model will explicitly include the heterogeneous nucleation and growth of the new phase, which is essential to understanding the kinetics of first-order phase transformations. Our explicit representation of the phase everywhere will enable us to directly simulate, for the first time, the macroscopic observable during experiments of first-order phase transformations under highly dynamic conditions such as observed at the LCLS (x-ray diffraction and scattering), DTEM (electron diffraction and imaging), and JASPER (wave propagation). The capability to explicitly model phase formation and evolution of multi-component systems in the presence of deformation is fundamentally new.

The direct simulation of microstructure morphology and composition during solidification and subsequent thermo-mechanical processing addresses conventional casting and wrought processes and novel manufacturing processes such as spray forming as being considered for the Transformational Materials Initiative. Our new capability will both increase confidence in Stockpile calculations and position the Lab for emerging missions such as the DOE Global Nuclear Energy Partnership.

Research Team

We have brought together a strong synergistic team from across the Lab focused on using the Lab's leadership position in high performance ultra-scale simulation to solve an important problem: the microscopic state following first-order phase transformation at extreme conditions.

Jim Belak, Fred Streitz and Dave Richards are statistical physicists using direct numerical simulation (MD, MC) to quantify phase transformations.

Patrice Turchi is an expert in alloy theory and thermodynamics of phase transformations and Bryan Reed is an expert on the crystallography of GB interfaces.

Nathon Barton is an expert in ALE3D simulations of high-rate deformation and a participant in the Petascale Initiative.

Milo Dorr, Jean-Luc Fattebert and Michael Wickett are experts in numerical methods for large scale computers, in particular, adaptive mesh refinement and advanced time integration and solver techniques.

Professors David Srolovitz and Long-Qing Chen are world experts in using Monte Carlo and Phase-Field methods to model microstructure evolution.